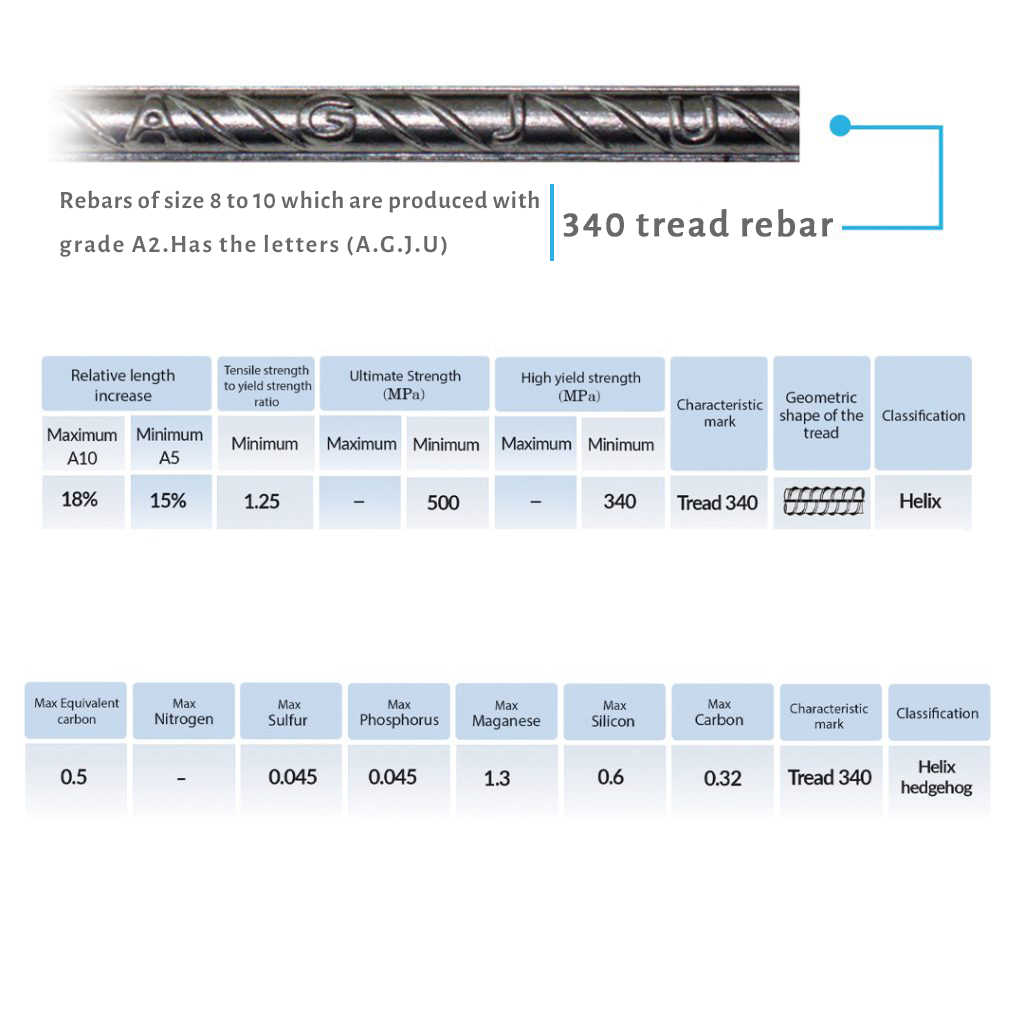

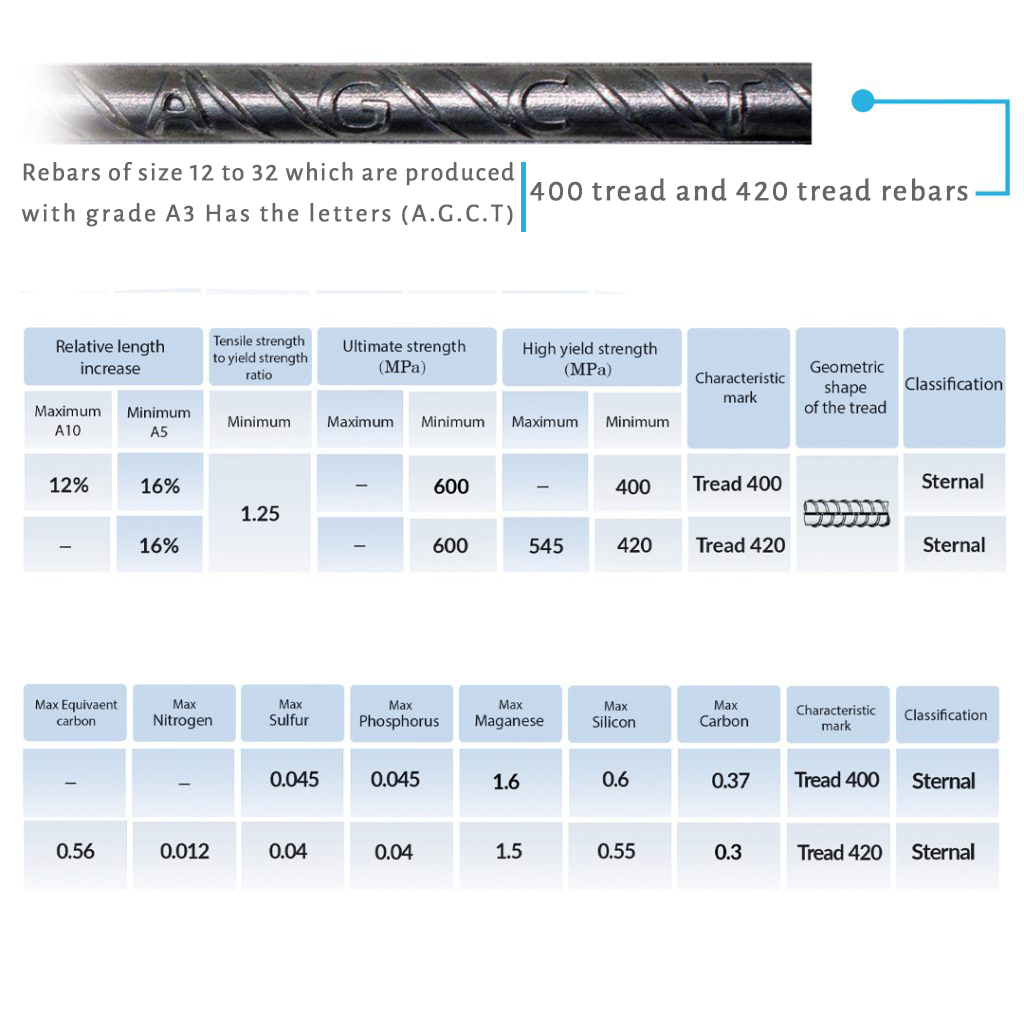

Two main and much in demand groups of rebar are popular in Iran called A2 and A3. These names come from GOST5781 standard of Russia. According to Iranian national standard of 3132, the abovementioned names are outdated and their equivalents are 340 and 400 ribbed rebars respectively.

A standard rebar must be conformed to the respected standard with respect to physical specifications such as nominal diameter, and rib geometric specifications as well as chemical and mechanical characteristics. Chemical compound of a rebar will help the constructor to attain rebars with desired mechanical specifications by selecting proper billets.

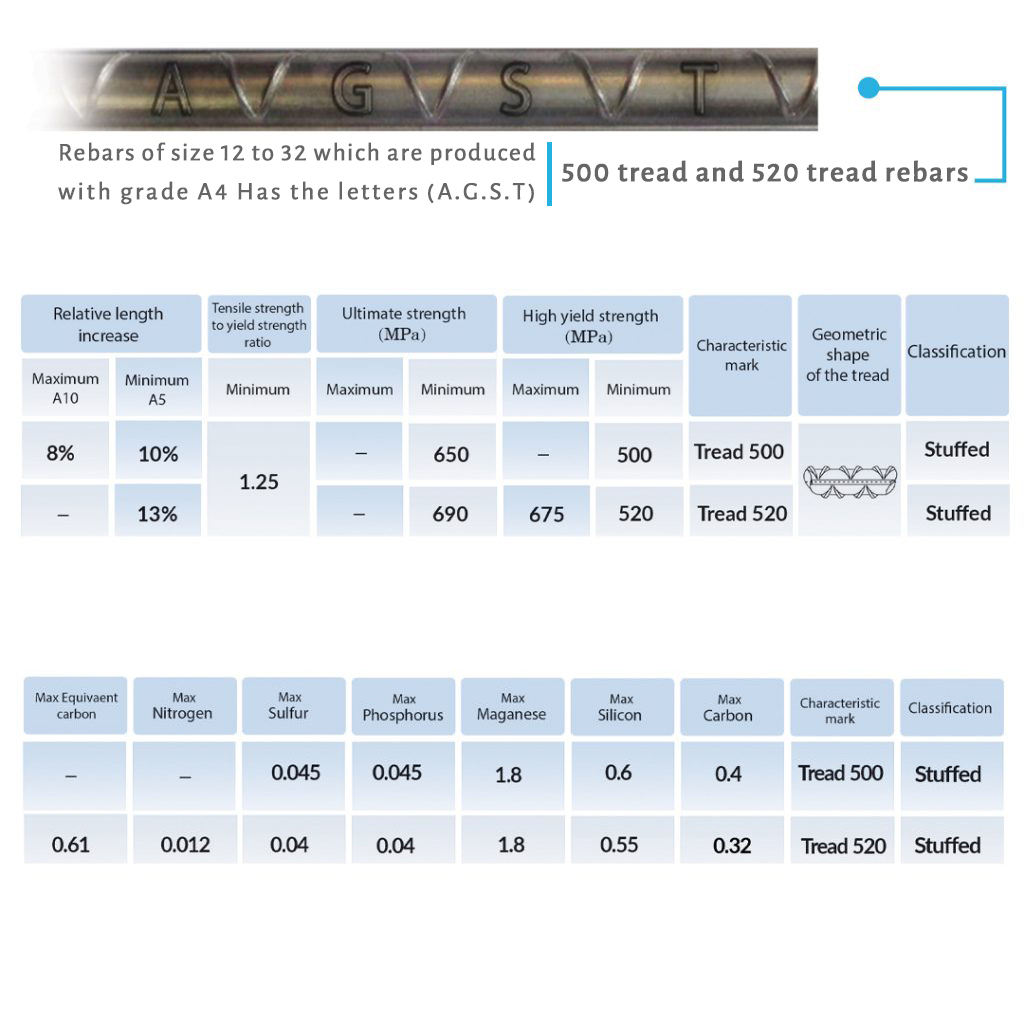

Design and geometrical details of ribs including pace, width and angle are important in curing rebar in concrete. Mechanical characteristics of rebar such as yield stress, tension strength, and relative elongation percentage will be determined in tension test. In fact Yield stress is the maximum tolerable strength which is not subjected to permanent deformation under the effect of imposed load. This strength is a criterion for calculations and selection of rebar’s type and diameter in structral design considering factor of safety. According to the mentioned significant importance, amounts of yield stress (340 and 400) have been used in steel specifications which indicate minimum yield stress of spiral and herringbone rebars (Mpa).

Relative elongation percentage and bending test are the criteria for rebar brittleness and flexibility and rebars must meet these expectations.